Automation of sample preparation in the analysis of oral solid dosage forms

Sample IN – Answer OUT is finally possible for HPLC analysis of tablets and capsules!

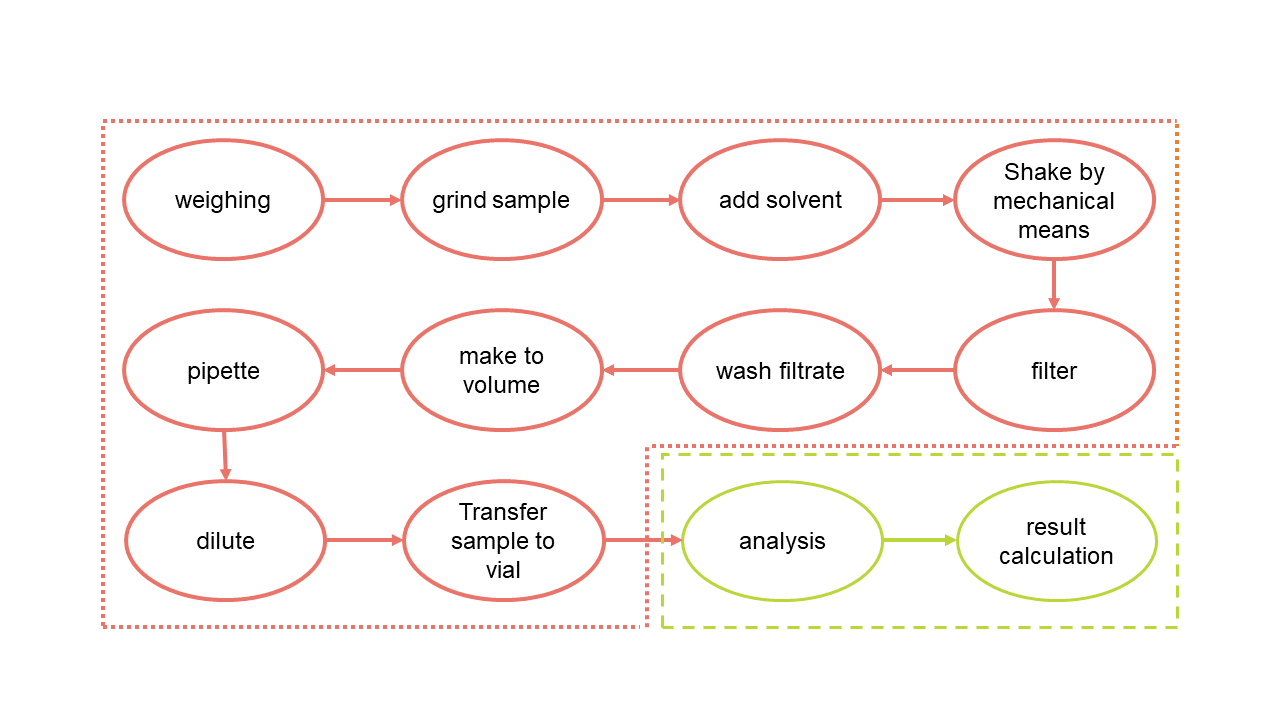

Content Uniformity and Assay in testing oral solid dosage forms (OSDs) are very time consuming and resource intensive. As the analysis is often done by HPLC, sample preparation is an important part of the testing procedure. Using approximately 60% of a lab technicians time, it is not only very time- and resource intensive, but also a large source of errors and variability. As the methods normally leave room for interpretation, every analyst performs the procedure differently, which makes standardization impossible. Furthermore, manual documentation of sample preparation often does not provide the traceability, which the authorities wish for.

Traditional automation approaches were either focusing on automating a single step or using a technology that requires washing between samples. This has the disadvantages of carry-over risks, cleaning validation and high solvent consumption. This leads to inflexibility and lack in robustness.

Weighing, Milling and dissolving tablets is a laborious and repetitive task. Even though it is often performed by well-educated professionals, human errors cannot be avoided. Errors cause highly unwanted Out of Specification (OOS) deviations, which again require resources for investigation and lead to problems in the supply chain (batch quarantine, etc.).

The pharmaceutical industry was lacking an efficient and robust solution to automate sample preparation for oral solid doses. Using a centralized extractor for all samples with washing in between has not brought the expected benefits. The approach of using disposable extraction tube to prepare the samples has been proven to be the only possibility of avoiding carry-over while offering flexibility and robustness.

With an increasing number of samples to be analyzed, resource management is important to accomplish the throughput. Manual sample preparation is the main bottleneck of laboratories analyzing oral solid dosage forms such as tablets and capsules. It is preventing a lab of developing towards standardized and digitalized workflows. With increasing competition and cost pressure, automating sample preparation is key for becoming lean labs. When scientists think of automation of sample prep, they often think of large sample quantities, which are prepared in the exact same way and offer no flexibility in the process.

As most laboratories handle a variety of samples with multiple techniques, automation solutions need to be flexible and multipurpose. The accroma is a modular system, which efficiently prepare solid samples for analysis. A robot moves disposable tubes to the different modules following customizable workflows. It processes the tubes containing samples through functionalities such as weighing, milling, dispensing, homogenization, extraction, ultra-sonification, dilution, centrifugation, and filtration. The sample preparation system can be interfaced to a Liquid Chromatograph analyzing the samples online. It intelligently optimizing the workflow process from sample to knowledge with uncompromised accuracy. The hands-on time for testing the uniformity of solid dosages and assay can classically reduced by 90%.

In contrast to other technologies cross-contamination are avoided and cleaning the extraction vessel is eliminated. This results in a reduction of solvent usage and an increase in speed. Since the extraction vessel is a consumable, the accroma SamplePrep system is very flexible, fast, and accurate, while making sample preparation traceable and safer.

accromas key technology is the disposable extraction tube, which holds up to 120ml and usually contains a steel ball. As the tube is closed with a lid, no evaporation takes place, which would falsify the results. The vertical shaking of the tube results in milling a tablet into fine powder or breaks up a hardgel or softgel capsule. This process is comparable with a ball mill. Defined amounts of solvents can be added to the tube by piercing with a needle through the septum in the lid. Every dispensed volume is subsequentially gravimetrically measured on the analytical balance with high precision and documented in the sample log file. Another advantage of the disposable sample tube is the parallel processing ability. While one sample is being analyzed, the other is in the milling process.

Leading pharmaceutical companies could reduce hands on time by a factor of ten and significantly eliminate Out of specification events related to sample preparation. The overall reproducibility and accuracy were increased while costs were significantly reduced.

We offer assessing the feasibility of automating your methods with the accroma by testing your products on the system before purchase. We offer you a success guarantee meaning if the method transfer is not successful, you can give back the system and you will get the money back.

Find out today whether the accroma system can be applied for your samples and methods. Get valuable insights of how hands on times can be significantly reduced. We will assist you in assessing accroma scientifically and economically. Contact us or book a demo without obligation.

Make sure you are the first person within your organization, which drives this initiative. Are you ready to improve accuracy while saving tremendous costs?