A Multi-Faceted Automated Sample Preparation Solution.

Easy Transfer of your Methods to Automation

Step 1

Sample Introduction

Step 2

Grinding

Step 3

Liquid Handling

Step 4

Extraction

Step 5

Filtration

Note: this is just a very basic example workflow, you have no limit in terms of numbers of steps and you are free in the order of the individual steps – discuss your methods directly with us.

Step 1

Sample Introduction

Introduce your sample and potential milling and / or mixing aids

Step 2

Grinding

Step 3

Liquid Handling

Step 4

Extraction

Step 5

Filtration

Note: this is just a very basic example workflow, you have no limit in terms of numbers of steps and you are free in the order of the individual steps – discuss your methods directly with us.

One Innovation – Three Major Advantages

Reproducibility

Flexibility

Speed

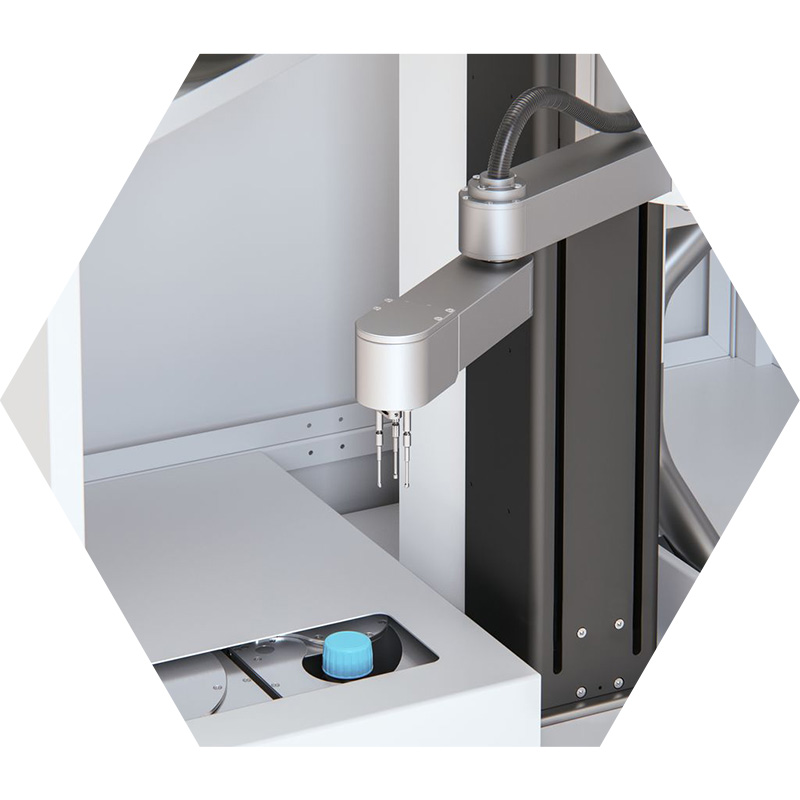

The accroma System

#1 Rack

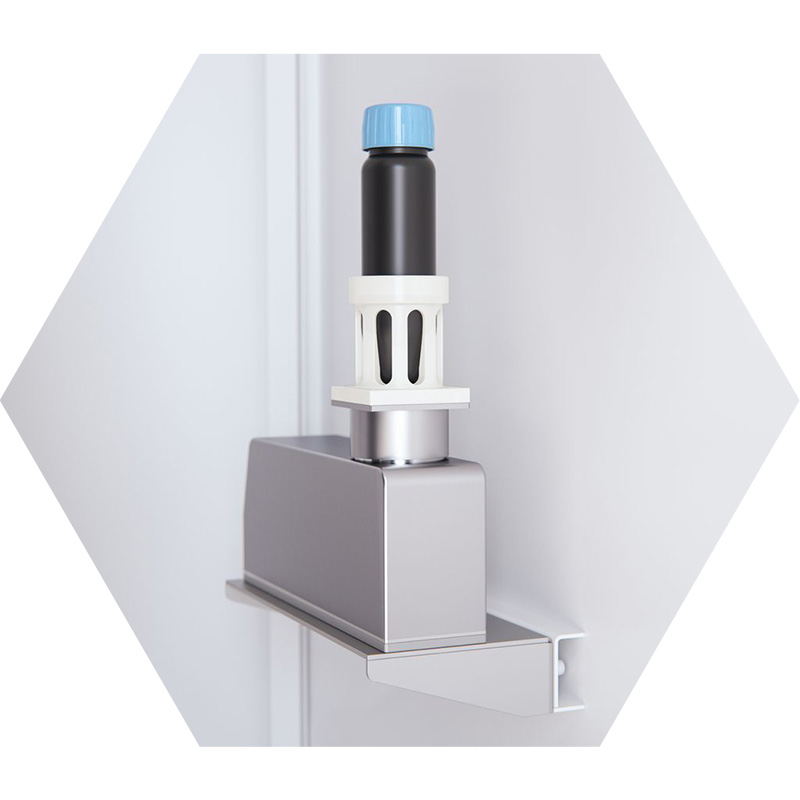

#2 Shaker

Extraction

Homogenization

#3 Analytical Balance

#4 Liquid module

#5 Ultrasonic bath – optional

#6 Centrifuge – optional

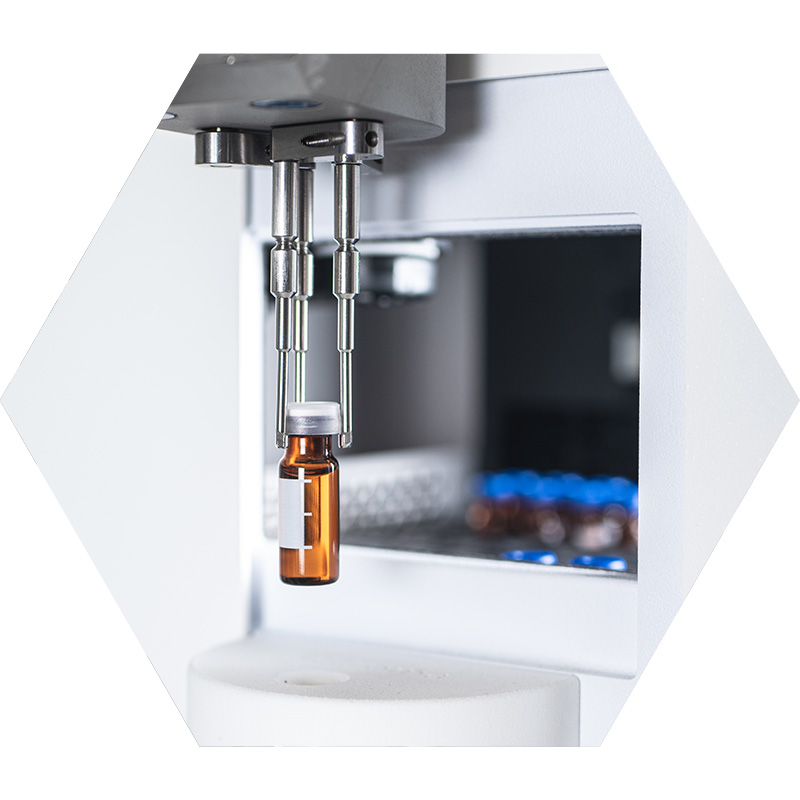

#7 Online Analysis interface – optional

Empower & Chromeleon

– Software Interfaces

Reinjection possibility

– no sample loss

LC autosample injections

– high precision

Waters & Agilent

– hardware interfaces

accroLab Software

Intuition Redefined

Ease of Use

1. Create a workflow

2. Prepare consumables

3. Assign workflow to one or multiple samples and start.

Your samples will be prepared unsupervised.

Security

Interfaces

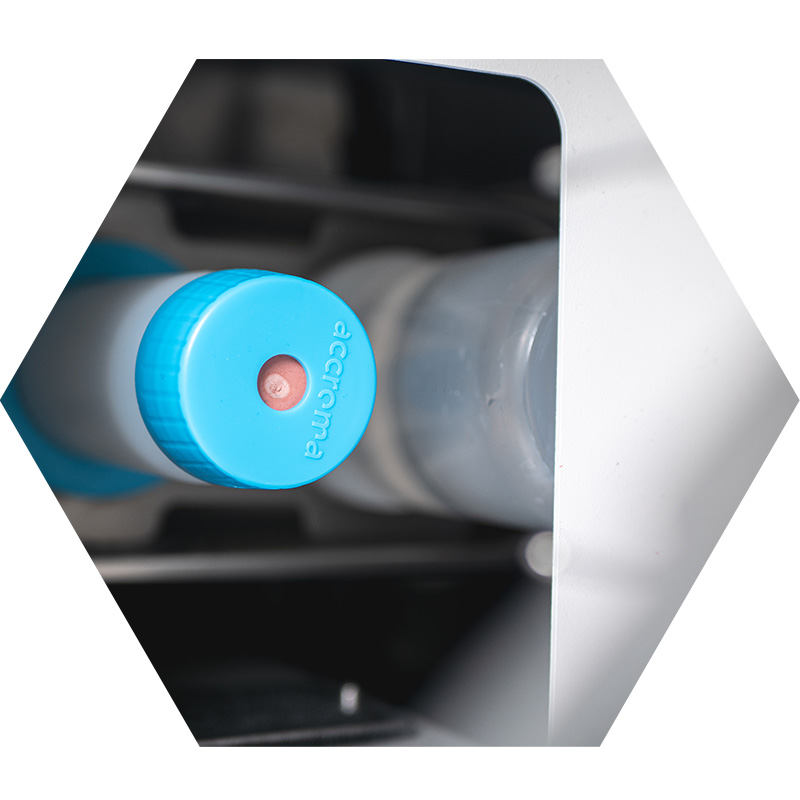

Your Tubes are Sustainable on the Second Look

To ensure scientific accuracy and reproducibility, accroma requires material of highest quality and inertness. Sustainability is important to us for which reason we use recyclable materials like polyethylene and iron. Both materials are 100% recyclable and can be reused as secondary raw materials. However, we need your help to separate content, tubes and steel balls.

Join the Future

Experts and laboratory specialists agree that the laboratory of the future is completely automated and digitized. However, this is easier said than done. Automating sample preparation of solid and semi-solid samples is challenging and was one of the missing pieces to make the Lab 4.0 possible. Other efforts are aimed at bringing the lab in a box directly to the process to enable real time release.